GRAM industrial processing equipmenT

Pumps and Accessories are the sole distributors of GRAM equipment in Southern Africa. GRAM industrial processing equipment is one of the world’s leading manufacturers and suppliers of flexible and efficient ice cream manufacturing solutions and equipment for producing ice cream. We are committed to providing the most efficient and flexible ice cream production and packaging equipment available on today´s market. We are backed by a highly motivated, talented and sincere people, and we have local sales offices and partners worldwide.

GRAM equipment includes filling, extrusion, molding, and wrapping of products, like molded sticks, cones, bulk/cups, sticked slices, cakes and sandwiches. Whether your need is new, remanufactured or used equipment, service of your existing equipment or genuine spare parts, GRAM equipment can help you.

When you face the task of starting new or upgrading your old equipment, you need the very best in your corner. GRAM equipment has been a global player within the ice cream equipment industry for over 30 years. We always strive to come up with new solutions that will make your production run even smoother.

Our offices in Philadelphia, Northvale, Denmark and Milan are backed by representatives all across the globe. This ensures that whatever or wherever the task might by, GRAM equipment will always be there for you.

Molding Equipment

WCB ice cream is a worldwide leader in equipment for the molded frozen stick confectionary industry. We produce molds made of stainless steel for all in-line systems, in-line and rotary bar freezers.

With molds from WCB ice cream you are able to produce an endless range of products, of many different shapes, sizes and combinations.

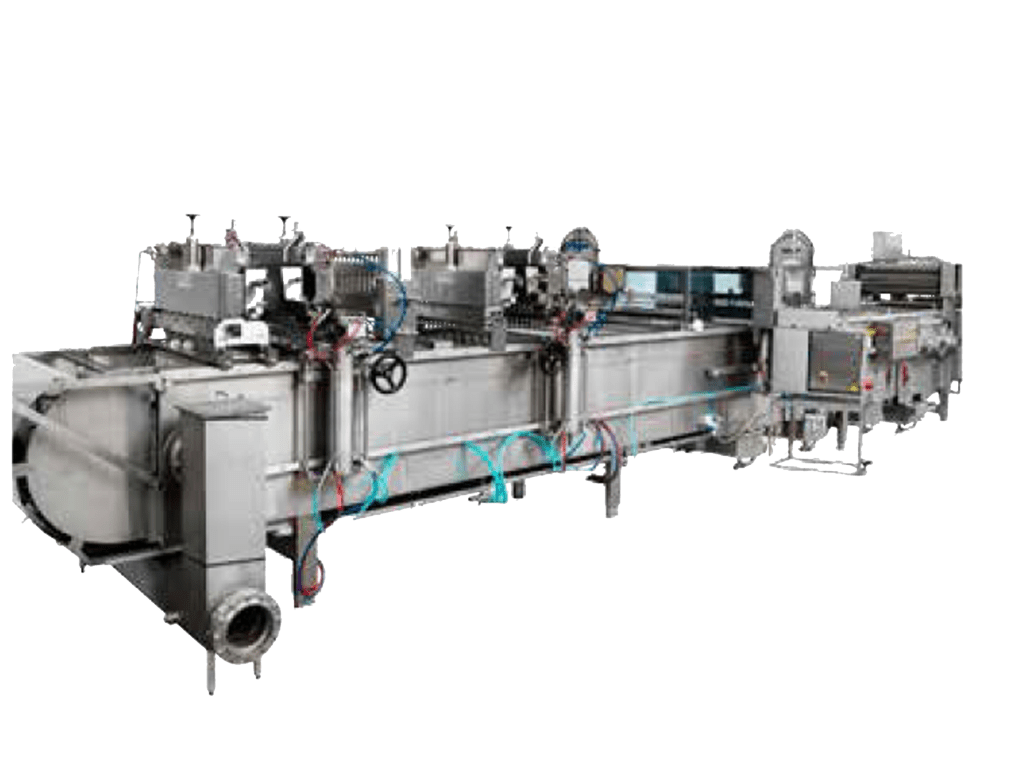

Extrusion Equipment

You can produce top quality ice cream with an Extrusion System from WCB ice cream. Freshly-extruded ice cream can produce a variety of items with a wide range of appealing tastes and textures, from sandwiches and cones, to coated slices and many more.

We offer a superior line of extrusion and hardening systems, each backed by advanced and innovative engineering.

Ingredient Feeders

Our Ingredient Feeders are designed to provide controlled insertion of any ingredient in a wide variety of shapes, sizes and forms into a continuous flowing stream of base product such as ice cream, peanut butter or pancake batter.

Positive, accurate metering is accomplished by means of an agitator and auger feeder combination, which transfers the ingredients from the main hopper into an enrobing rotor at a controlled rate.

Laboratory Equipment

The fully pre-assembled Universal Pilot Plant simulates production processes and allows for research and development testing for new products and formulas. Ideal to experiment with small batches and simulate full-scale production testing.

A variety of optional equipment is available, including laboratory equipment, brine freezing system, cut and extruding system, fruit and ingredient feeder and ripple pump assembly.

Filling Equipment

For some ice cream products, the shape is distinctive; for others, it is traditional; for others again, it is practical. WCB ice cream offers the ice cream filling equipment you need.

Whether the form is cones, cups or cartons, WCB ice cream offers a wide range of filling equipment to help you getting your ice cream products from your freezers to the consumers.

Freezers

The continuous ice cream freezer is the very heart of every ice cream production system. Choosing the right ice cream freezer is the key to both product and production goals.

Consistent, repeatable ice cream production is the ultimate goal of any ice cream operation. To achieve it, we help you to explore all issues that influence your equipment choice and the ultimate system success.